Maarschalkerweerd St John Basilica in Oosterhout

€ 349,-

On October 24 and 25, 2022, we recorded the Maarschalkerweerd organ of the St John Basilica in Oosterhout for Hauptwerk.

From 1758, the Church of St. John the Baptist in Oosterhout had a single-manual organ with attached pedal, built by J.H.H. Bätz.

At that time, the church was in use by the Reformed community.

In 1810, the building returned to Catholic hands. The organ underwent a minor modification to its specification in 1838 and was repainted in 1864.

Twenty years later, the instrument was no longer playable, and a harmonium was used during services.

In June 1888, the church council of the St John signed a contract with Michaël Maarschalkerweerd (1838–1915) from Utrecht for the construction of a new organ.

The firm Maarschalkerweerd & Zn. delivered the new organ for the St. John in Oosterhout in 1890.

At the end of July that year, the Amsterdam organist Jos Verheijen inaugurated the instrument.

The original design featured a specification with 23 stops, divided over two manuals and a free pedal.

The console was positioned independently.

Under Verheijen’s influence, a Quintflute 6 was added to the Great Organ during construction, and the originally planned Flageolet 2 on the Positive was changed to a Cornet I–III.

Maarschalkerweerd built the organ in two pine cases, which were placed on either side of the large west window in the tower.

In the case on the left (as seen from the church), he installed the Great Organ along with the main bellows; in the right case, the Positive and Pedal were placed.

The main bellows featured double folds and two scoop bellows. Each of the three divisions had its own regulator bellows,

which were connected to the wind chests via accordion-like tubes.

The wind chests are aligned parallel to the tower walls, except for the Positive’s chest, which was set at a slight angle.

The chests are made of oak with matching runners and sliders. The pipe shoes and pipe racks are also made of oak,

with the pipe shoes reinforced with mahogany. The Great Organ has two chests: one for the principal stops and one for the combination stops.

The Positive was equipped with a swell box.

The reason for this design is unknown, but the cases were not given a traditional pipe front and were instead finished with paneling,

giving the organ a somewhat unusual and unique appearance. The cases were partly adorned with ornamental mesh. They had no solid roof, which was also fitted with mesh.

The panels on the angled fronts of both cases were painted with stenciled decorations.

The right case also contains the louvers of the Positive’s swell box.

Maarschalkerweerd placed the oak console in the center of the organ loft between the two parts of the organ,

at the level of the “front lines” and with a clear view of the chancel. The stop knobs are arranged in three tiers on both sides of the manuals.

The knobs are made of rosewood with porcelain nameplates, and the keys are covered with ivory and ebony.

The Positiv’s bass coupler pedal is located in the center of the console; the couplers are operated by pedals, as is the engagement of the combination stops.

Maarschalkerweerd constructed the stop action from the console to the wind chests as a traditional mechanical tracker system.

For the key action, however, he chose an innovation: the electro-pneumatic (-mechanical) system patented in 1881 by William Ford Schmöle from Philadelphia and Alexis Mols from Antwerp.

The electro-pneumatic device they developed was relatively simple in design and easy to integrate into a conventional tonal layout.

Furthermore, the magnets did not need to exert the great force required in other electro-pneumatic systems, which was advantageous for power consumption.

The system was popular among organ builders eager to experiment.

In France, for example, Joseph Merklin applied this system in several organs; César Franck, as a member of inspection committees, was positive about it.

In 1887, the Franssen brothers used it for the first time in the Netherlands, in their organ for the “Irene” building of the Dutch Protestant Union in Rotterdam.

In Oosterhout, the power supply for the magnets was provided by a battery consisting of four galvanic cells, so-called “Leclanché elements.”

Each element contained copper oxide, zinc, and caustic potash.

The elements were manufactured by the firm La Lande et Chaperon and supplied by Louis Digeon & Cie. from Paris.

The battery was equipped with a “shutter” (the term Maarschalkerweerd himself used), so that it was only connected to the electrical circuit when the bellows were filled.

This ensured that the battery would not run down when the organ was not in use.

Maarschalkerweerd assured that the elements would work “regularly and for a long time, as experience has shown.”

To create space in the wind chest for the pneumatics and magnets, the valve boxes were raised by about ten centimeters.

Around the same time, Maarschalkerweerd applied electricity in the Schmöle-Mols style twice more: in the organs of the St. Dominic Church in Nijmegen (destroyed in 1945) and the St. Martinus Church in Doesburg, both dating from 1889.

With the exception of the reed stops, which were ordered from G. Masure in Paris, the pipework for the St John organ came from Maarschalkerweerd’s own workshop.

He voiced the Oosterhout organ quite broadly, a practice he continued in his instruments for Paramaribo (cathedral, 1890), Sneek (St. Martinus, 1891), Amsterdam (Concertgebouw, 1891), and Delft (Maria van Jesse Church, 1893).

Ten years after its completion, in 1900, the electrical part of the key action no longer functioned satisfactorily.

Maarschalkerweerd replaced the wiring between the console and the wind chests with pneumatics, making the key action entirely pneumatic from that point onward. The electrical system of the organ in Doesburg had undergone a similar change shortly before.

The batteries used were unable to provide a consistently sufficient current to operate the magnets properly. Wear on the galvanic cells likely contributed to this problem. Interestingly, Maarschalkerweerd did not remove the magnets when converting the action in Oosterhout. It is probable that during this conversion, the sub-octave coupler from the Great Organ to the Positive was lost. It is unclear whether this had originally been mechanical or electrical.

Very little information can be found in the archives about the instrument’s history up to the 1960s. At some point, however, an electric blower was installed.

In 1964/65, the organ underwent tuning and maintenance by the firm Pels from Alkmaar, and in 1968, the firm Verschueren from Heythuysen lubricated the blower, as noted inside the motor case. Shortly after the Second Vatican Council and its changes to the liturgy, interest in the Maarschalkerweerd organ declined.

In 1965, the parish acquired a unit organ from Verschueren, which was placed at the front of the choir. In 1977, the same organ builder replaced the unit organ with a two-manual mechanical instrument, also placed in the choir. Meanwhile, the condition of the large organ deteriorated. The low point was the relocation of the pedalboard to the organ loft, during which the pedal and Positive stop action was cut without hesitation. Shortly afterward, the electricity to the organ blower was disconnected for safety reasons. The instrument became heavily soiled, and a burglar damaged some of the pipes.

Interest in the instrument was revived in the 1990s. Careful plans for the organ’s rehabilitation were developed.

However, urgent issues with the church building delayed progress. Once those were addressed, the parish could refocus on restoration plans for the organ. In 1999, Jos Laus (on behalf of the KKOR) prepared a historical report and a restoration plan. The Dutch Cultural Heritage Agency was involved due to the organ’s historical significance.

In addition to the general historical value of the largely unchanged instrument, there was a particularly intriguing possibility that the electrical part of the key action could be reconstructed. After all, the majority of the original electrical components, magnets, and pneumatic bellows with their accessories were still present.

After the organ was granted protected monument status in September 2003 and national funding was promised, decisive action could be taken. Of the three organ builders who submitted bids, the firm Elbertse from Soest was chosen to carry out the restoration. The restoration began in January 2005 with the disassembly of the organ. Incidentally, the firm Elbertse has a special connection with Maarschalkerweerd: the grandfather of the current director had been a master assistant to Michaël Maarschalkerweerd before starting his own company.

The cases were restored and missing parts replaced. The damaged decorative mesh was repaired, with the best preserved old parts reused for the most visible panels. A small modification involved creating an opening in a previously solid panel to enhance the speech of the Open Subbass. The original paintings were refreshed, and the elevation of the choir floor between the two organ cases was renewed.

The console was cleaned and waxed, and the lower keys were re-covered. For the restored electrical sub-octave coupler between the Great Organ and Positive, a new pedal was made and installed in the original position. The iron stop rollers and rods were repainted black, and the pivot points were inspected and repaired.

The wind chests were completely dismantled, the sliders aligned, valves leveled, and re-covered. The pull eyes on the valves were re-festooned. Woven rings were glued between the trackers and pipe shoes, and the pipe racks were realigned. In a few places, additional hangers were added for the stability of the pipes.

The stop action of the Positive and Pedal could be restored using material that had been previously cut away but was still present in the organ. To make the operation of the stops easier, counterweights were added to the stop rods.

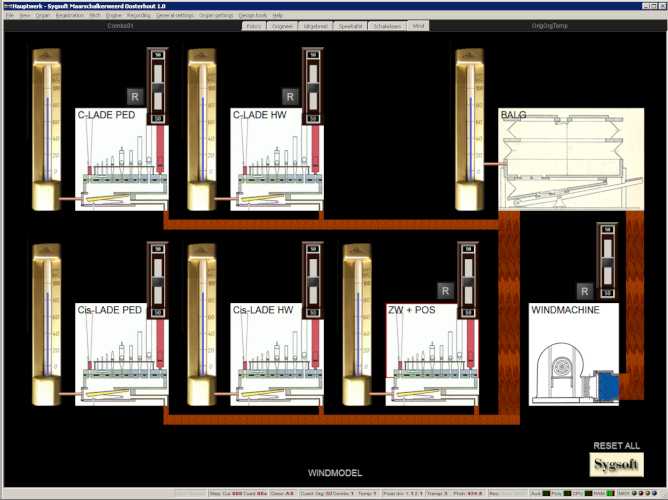

The reservoir bellows, the three regulator bellows, and the harmonic tubes were re-covered. The wind channel damaged during the relocation of the pedalboard to the organ loft was repaired. Using archival information, the original wind pressures were restored, as the remaining bellows weight proved sufficient, indicating that the pressure had never been altered. A new blower in a sound-dampening case was installed so that the original scoop bellows pedals could remain in place, though they are no longer in use.

The pipework was restored, broken side pipes and tuning devices were repaired, and missing pipes were replaced.

The most challenging part of the restoration was the reconstruction of the complete Schmöle-Mols system for the key action. No functioning example of this system existed in the Netherlands at the time. To gain a clear understanding, a full-scale working model was first built. The reconstruction required the removal of the tube pneumatics installed during Maarschalkerweerd’s earlier conversion.

Electrical contacts were installed in the keys of the console, and new wiring was laid between the console and the wind chests. A modification was made compared to the original 1890 design. The magnets require a significant amount of power, which puts considerable stress on the key contacts and accelerates wear.

The circuit was divided into two parts: the key contact now triggers a “booster” with relatively low power, which then supplies the magnets with the required high power. Several magnets were missing and had to be replaced with newly made copies; a few existing magnets were rewound. The wedge bellows in the wind chests were re-covered.

From May 2006, the organ was reassembled in the church. On October 1, 2006, the restored instrument was inaugurated by the then organist of the St John, Hans Avontuur. This marked the conclusion of a ten-year period of church restoration.

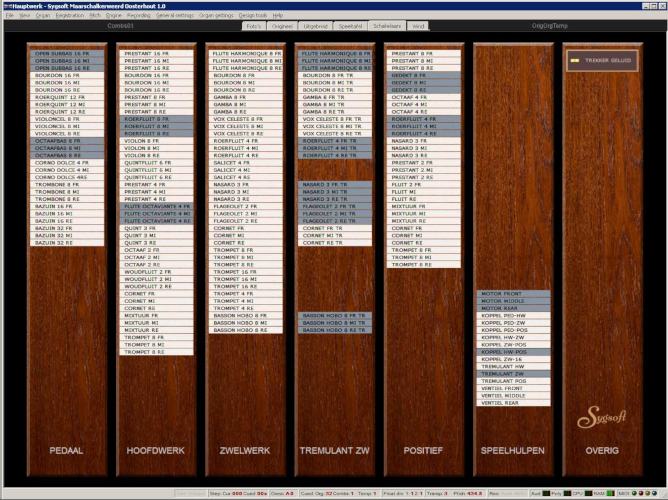

This sample set was recorded in stereo (24-bit 96kHz) from three positions.

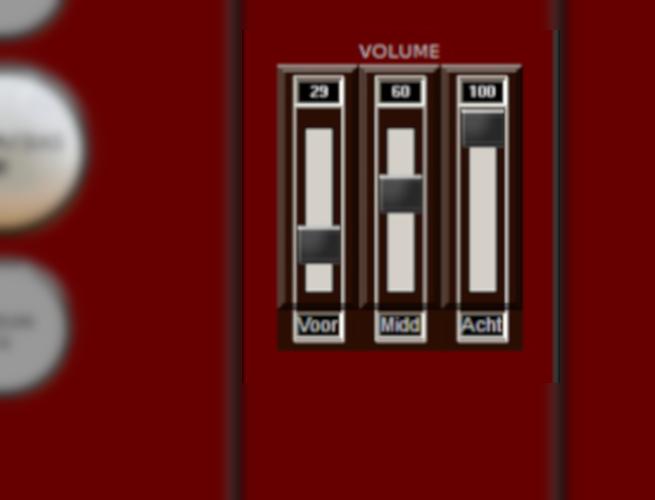

The set uses the 3-channel technology developed by Sygsoft, allowing the user to adjust their listening position.

For the Great Organ, Swell Organ, and Pedal Organ, you will find three sliders:

1: Front – recorded very close to the organ. This provides a very direct sound, ideal for practice purposes.

2: Middle – recorded at approximately three times the distance used for the front position.

3: Rear – recorded far from the organ.

Using three sliders (0–100%), you can create a mix of the three positions according to your preference.

The Positive Organ (choir organ) can be adjusted separately in the same way.

For more information, see the System Requirements tab.

The recordings for this sample set were made in October 2022.

Recording quality: 96 kHz 24 bit. For the set reduced to 48 kHz 24-bit.

Number of microphones: 6.

Number of samples processed in this set: 25,275.

Number of lines in the Organ Definition File: 1,500,000

Christian Boogaard:

Noise reduction, adjustment of wind model, voicing, demos, artistic advice, and overall direction.

Johan van der Waal van Dijk:

Processing of the samples and technical advice.

Fred de Jong:

Layout, additional sample checks, loops, and ODF programming.

Wenneke Boogaard:

Administration and web design.